Circuits & Electronics and Structures & Material Combined 2D Project

EPD Term 4

Nov 2014

For our 2D project, we had to come up with a healthcare product which could be assistive or rehabilitative. We also had to incorporate at least one physics concept from Circuits & Electronics and Structures & Materials into our design.

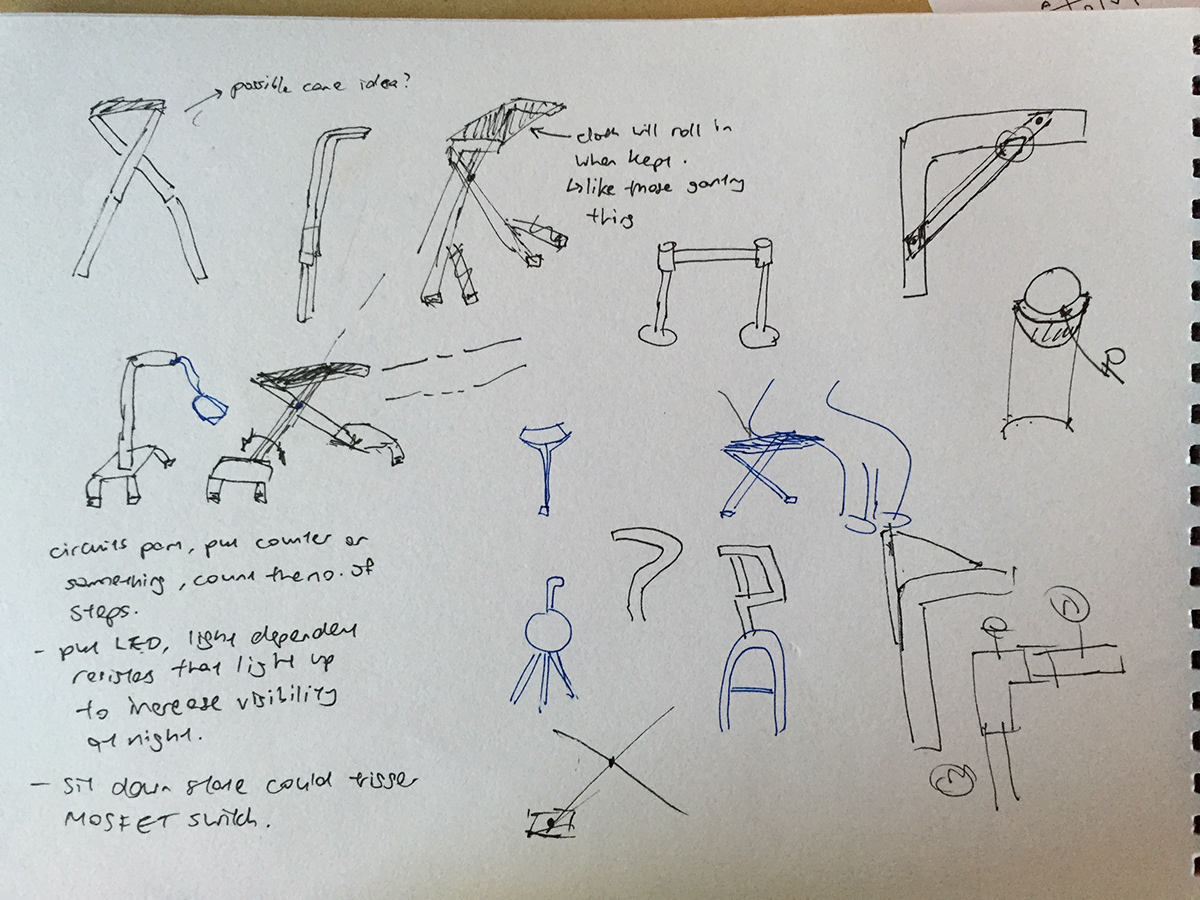

After a few ideation processes, our group seemed geared towards building a walking cane which could be converted into a chair. However, we wanted the seat mechanism to be less intrusive unlike current designs already in the market.

Initial ideation

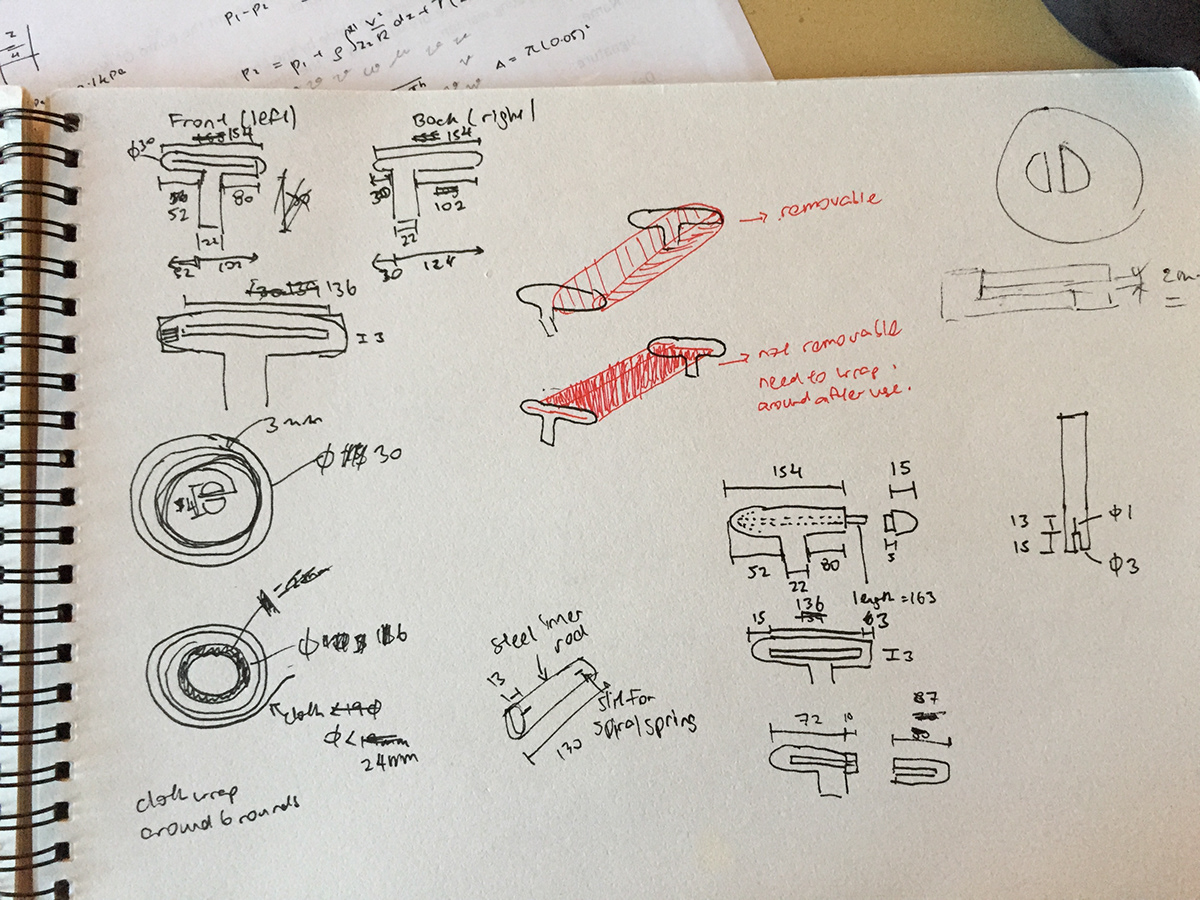

Designing the base and the legs

Inspired by the measuring tape, we wanted to adopt a similar mechanism which would feed a piece of cloth when the handles were pulled apart. And the cloth would automatically be retracted back when the handles are pushed together.

It was quite challenging trying to incorporate this into our product and we had to dismantle a measuring tape to understand how the torque spring actually worked and modified the parts to suit our prototype.

Designing the handle

The handle was complex as it had to be big enough to contain the torque spring and cloth but small enough to be held in one hand. A lot more thought and consideration went into deciding the shape and dimensions of the finalised handle.

The electrical component consisted of LED strips located at the base of the cane to help the user see better in low visibility and also make the user stand out more in the event of oncoming traffic.

Electrical Schematic Diagram which involves logic gates and MOSFETS to control the intensity of the LED.

The handles had to be 3D printed due to the complexity of the design. Many iterations of the handle had to be done as well as we encountered new problems every time we fabricated the handle. The final version of the handle had a slight funnel located at the ends of the cylinder in order to fit the torque spring mechanism easily. The length of the handles had to be compromised as well due to size limitations of the 3D printer.

Close-up of the 4th interation of the handle.

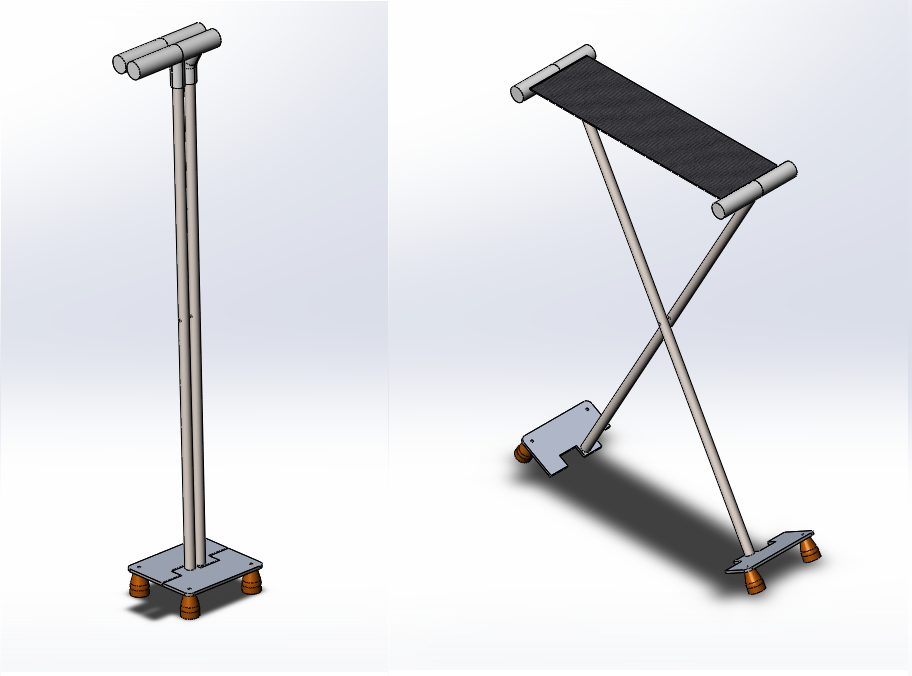

CAD done in Solidworks.

CLOSED and OPENED states.

The finished prototype in its closed state.

In its opened state.

LED strips located below the cane to increase visibility for the user and others around them.

Testing our product.

Unfortunately, the chair wasn't fully functional as it could only tolerate a small amount of weight. The weakest part would be the customised torque spring which would not be able to hold the weight of an average person. Even if it could, the 3D printer ABS material would bend or break under the pressure as well. The poles were also too thin but we had to make do with what we had.

We failed to implement the electrical component as designed as well. What we thought would work in theory ended up having several complications which burnt a few logic gates. Due to the lack of time, we couldn't remedy the problem before the deadline.

Despite the failure, it was a good learning experience for all of us. We gained a deeper understanding of structures and deciding what materials to use.

The team consisted of Chow Wong Chong, Timothy Syn and Kenneth Loh.